Products

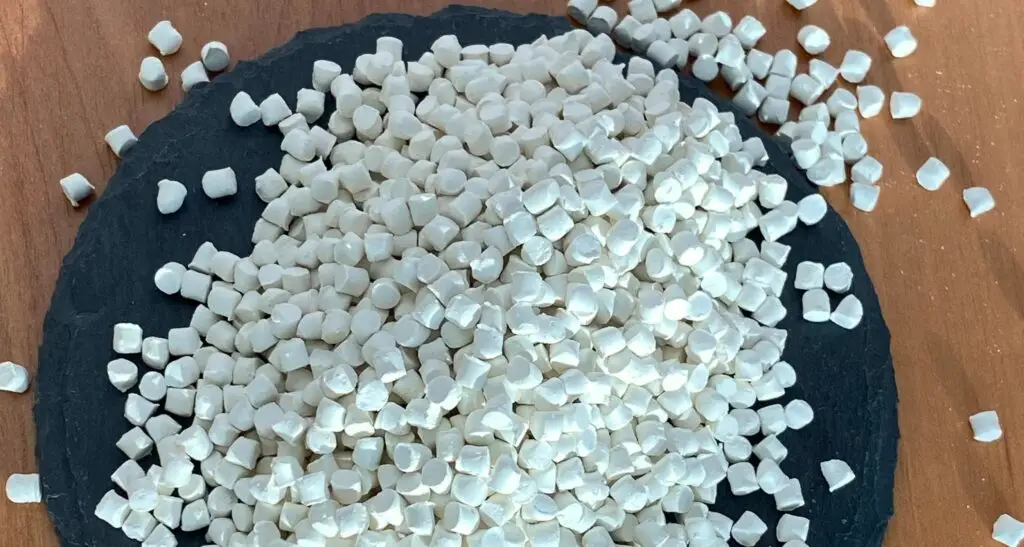

Harcane Powder Injection Molding Feedstocks produced through an optimized process which highly reduces the production costs, lead to very competitive prices and performances.

The injection material exhibits the feedstock properties that made Harcane’s reputation, as:

- Low viscosity, which allows to completely fulfill the prints and to perfectly weld the lines. The Harcane feedstock properties offer to inject CIM parts with the same parameters as for plastic injection, which means with a low pressure and short injection cycles. A low viscosity is also required for multiple prints molds – molds until 16 prints are currently set with this feedstock.

- Reduced cycle time. With such a short cooling time, the complete cycle time for a 1 cc part, for example, can be brought under 10 seconds. The decreased cycle time combined with a multiple prints mold, places the CIM process as an alternative to pressing processes, while adding the very important advantage of the 3D shaping.

- High density and high mechanical properties, the organic materials in Harcane feedstock formulation provide an optimal densification of the green part, resulting in a very high sintered density. The obtained density is relatively 0.01 to 0.02 g/cc higher than obtained by pressing, with a ready-to-press material.

- A 100% thermal de-binding material can performed – besides standard solvent debinding capability – which eases significantly the global production process. According to the volume of the parts and to their wall thickness, the maximum complete cycle time – including the sintering operation – is about 72 hours for small parts to 120 hours for parts with a 4mm section. An equipment adapted to a pressing process with a ready-to-press material can be used for the thermal de-binding of Harcane’s PIM feedstocks.

- Oversizing factors compatible with all other feedstock factors, allowing the user to keep their own molds without any modification.

Feedstocks Advantages

- Raw materials from solid partners: ultra-fine powders, nano powders, innovative High Impact powders

- Feedstock manufacturing: portfolio of more than 200 exclusive formulas for almost all inorganic powders

- Injection: low injection cycle

- Green part stage: very good machinability

- Thermal de-binding (IPA possible)

- Near Net Shape – No deformation after sintering

- Lower production costs vs competition

HIC – High Impact Zirconia ceramic feedstocks

Meeting the performance and cost requirements of its

clients, HARCANE industries offers several

families of ZrO2 Zirconia feedstocks for CIM – Ceramic

Injection Molding